Towards Improving Banking Services Quality

16.

Waste Walk

Introduction

to Waste Walk

A waste

walk is a structured approach to observe work processes, identify waste,

and propose actionable solutions to improve efficiency. It is a cornerstone

activity in Lean management, emphasizing the importance of "going to the

Gemba" (the actual place where work happens) to uncover inefficiencies.

Often, individuals working within a system become desensitized to waste over

time. A waste walk provides a fresh perspective, making waste visible again. By

actively involving a team and methodically observing processes, organizations

can systematically eliminate waste, enhance value delivery, and foster a

culture of continuous improvement.

A waste

walk is simply a planned visit to where work is being performed to observe

what's happening and to note the waste. It is a maxim in lean thinking that to

fix any problem you must first see the waste. However, the longer you have

worked in a system, the harder it is to see the waste around you. Taking a

“waste walk” is one way to make the waste visible again.

A waste

walk is a primarily a group activity to identify wasteful practices taking

place within a business process. First gather a group together; agree on a

route and then walk the process. On the way round look for the common wastes

associated with the business, as described above. Depending on the group's size

it is better to choose to have some people focusing on specific wastes types,

which can certainly improve the rate of spotting wastes. A waste walk supports

Lean management. A waste walk can be effective if following points are take due

care.

Before

the Walk

To

ensure the effectiveness of a waste walk, certain preparations are essential:

·

Understand the

Process:

Team members should familiarize themselves with the process being observed,

including key steps and objectives.

·

Have a Process

Flow Diagram Handy:

A flow diagram serves as a visual guide for understanding the workflow and

identifying bottlenecks.

·

Keep a Waste

Walk Form:

The Waste Walk Form is a tool to record observations of waste and suggested

solutions systematically.

During

the Walk

The

waste walk itself is an interactive process involving team members, operators,

and managers. The following practices ensure a successful observation:

·

Introduction:

Begin by explaining the purpose of the visit to the process operators. A

respectful approach builds trust and cooperation.

·

Ask Relevant

Questions:

Engage the operators with thoughtful questions about their workflow and

challenges they encounter.

·

Listen

Actively:

Carefully note the operators’ inputs and perspectives, which can provide unique

insights into hidden inefficiencies.

·

Document

Findings:

Record all observations, including types of waste and possible solutions, in

the Waste Walk Form.

·

Express

Gratitude:

At the end of the walk, thank the operators for their time and input.

Types

of Waste Identified

During

the walk, the team may encounter various forms of waste, such as:

·

Poor layouts

affecting process flow.

·

Ineffective

maintenance causing delays.

·

Bureaucratic

processes that add no value.

·

Excessive

reporting or redundant documentation.

These

issues reduce performance and profitability and must be documented for further

analysis.

After

the Walk

The

waste walk does not end with observations. Post-walk activities ensure the findings

translate into actionable improvements:

·

Share

Observations:

Discuss findings with the process operators to validate observations and refine

proposed solutions.

·

Mark Wastes on

Visual Tools:

Update the flow chart or value stream map to highlight wasteful areas and track

improvement opportunities.

·

Plan and

Prioritize Improvements:

Develop an action plan to implement changes and monitor their impact on the

process.

After

the Walk

-

Team should

share observations and findings with the operators

-

Mark wastes on

the flow chart / value stream map

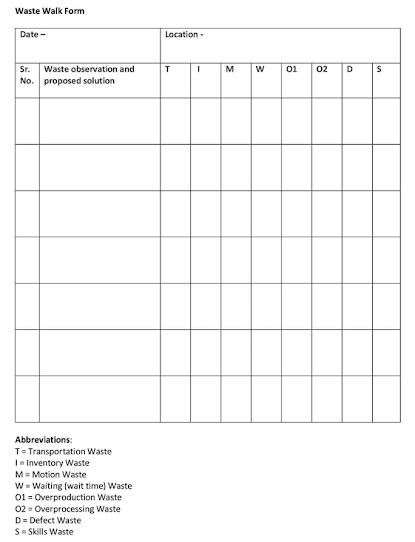

Waste

Walk Form

A Waste Walk Form is

illustrated in the Figure 10.

Figure 8

- Waste Walk Form

Waste

Walk in Banks

In

banks, waste walks should ideally be conducted by a cross-functional team

comprising individuals from different levels of the organization. The key

participants may include:

1.

Process Owners

·

These should be

managers or officers responsible for specific processes (e.g., loan processing,

customer service, account management).

·

They should have

in-depth knowledge of the process and can provide valuable insights during the

walk.

2.

Lean Experts

·

Lean expert

professionals are trained in Lean principles and can guide the team in

identifying and categorizing waste effectively.

·

They are able

to bring a structured approach to spotting inefficiencies and proposing

solutions.

3.

Senior

Management Representatives

·

Involvement of

senior officers (e.g., department heads or branch managers) may demonstrate commitment

to Lean principles.

·

They can ensure

that identified improvements align with the bank’s strategic goals.

4.

Frontline Staff

/ Process Operators

·

Employees who

perform the actual work (e.g., tellers, loan officers, customer service agents)

are critical participants.

·

They have

firsthand experience with inefficiencies and can provide practical insights.

5.

Internal

Auditors

·

These team

members bring an objective perspective to the walk and ensure compliance with

regulatory requirements.

6.

IT and Support

Team

·

Banking

processes often rely heavily on technology. Including IT professionals helps

identify waste related to systems, such as software inefficiencies or

bottlenecks in digital workflows.

7.

External Consultant

·

If the bank

lacks in-house Lean expertise, hiring external consultant can provide a fresh

perspective and expert guidance.

Key

Considerations:

·

Team Size: Keep the group manageable (4–7 participants) to ensure focus

and efficiency during the walk. The team should not be too big.

·

Training: All participants should have basic training in Lean

principles and waste identification.

·

Collaboration: Promote open communication and teamwork to ensure a

comprehensive view of the process.

By

involving the right mix of individuals, banks can conduct effective waste walks

that identify inefficiencies and drive meaningful improvements in customer

satisfaction, compliance, and operational efficiency. During the waste walk

team members should also interact with customers to understand their needs and

expectations.

Conclusion

A waste

walk is more than a diagnostic activity—it is a collaborative exercise that

strengthens team awareness and involvement in continuous improvement efforts.

By using tools like the Waste Walk Form and adhering to Lean principles,

organizations can identify inefficiencies, engage employees in problem-solving,

and achieve operational excellence. For the banking sector, where precision and

customer satisfaction are paramount, the waste walk provides a pathway to

leaner, more efficient processes that directly benefit customers and

stakeholders alike.

I welcome your comments, questions and suggestions.

Warm regards,

Keshav Ram Singhal

No comments:

Post a Comment